Josh Smith was 11-years old when he hand forged his first hunting knife. Within a year, he bought a belt grinder with money he earned mowing lawns and working in his father’s excavating business. More equipment followed, and by his early teens, Smith became one of the world’s youngest certified knife makers.

He continued to hone his knife-making skills for decades and eventually quit his day job as a power line technician in western Montana to pursue knife making full time. Today, his Montana Knife Company (MKC) knives are among the most highly-sought blades in the hunting industry. And his team of some 70 employees can scarcely keep pace with skyrocketing demand that only seems to grow by the day.

We caught up with Smith earlier this year during a visit to his shop in Frenchtown, Montana—a tiny interstate stopover about 45 minutes northwest of Missoula. Inside a built-out pole barn on property next to his home, Smith and his team handle every aspect of the production process before shipping MKC knives to customers scattered across the country and the globe.

Smith is a lifelong hunter who grew up in Lincoln, Montana. He started making knives around the time he learned to hunt elk and became a journeyman bladesmith at 15—making him the youngest knife maker to ever earn the title. By 19, he'd obtained Master Smith status from the American Bladesmith Society.

He worked as a high-end custom knife maker for a decade but gave it up in for steady work with a local power company when the economy tanked 2008. "I ended up getting divorced, my house burned down, a bunch of stuff," Smith said. "But after I got remarried, I was telling my wife about this idea of Montana Knife Company, which I'd had trademarked since I was 19." It was Smith's wife Jesse who encouraged him to take the dream full time back in 2019.

With MKC, Smith dreamed of making custom-quality knives tailored to the unique needs of big game hunters. And he wanted those knives to stand up to harsh wear and tear and remain in the field year after year—for generations even. "I kept seeing what was available in the box stores, and I felt like I saw the quality going down," he said. "I started seeing more and more well-known companies outsourcing stuff to China. I felt like things were getting cheap, and the respect of the knife was actually dropping with the advent of replaceable blade knives."

When he worked as a custom knife maker, Smith often found himself reconditioning heirloom knives passed down from father to son, or from a grandparent to a grandchild. "A lot of people would come into my shop and say, 'This is my grandfather's knife. Can you sharpen it for me?' or 'Can you fix the tip on this? My grandpa carried it in Vietnam' or 'He hunted in Alaska with it,'" Smith said. "As hunters, we've always passed down knives and guns. Now all of the sudden we're throwing them away? That really bothered me."

Smith officially launched MKC in February 2020 at a hunting industry event called Winter Strong in Leesville, South Carolina. "There were some industry people at the event, and I was telling them about my idea for this company," he said. "I didn’t even have a website at that point. It wasn’t a company at all. It was just an idea." Later that year, he hired Brandon Horoho, now his full-time business partner and co-owner of MKC, to head up the brand's marketing presence.

Horoho and Smith continued selling knives at hunting expos and trade shows and quickly built a niche following. "We only hired two employees throughout the first year," Smith said. "We were making a lot of mistakes and just learning as we went along. By 2022, we were really starting to role, and last year (2023) was our biggest year yet."

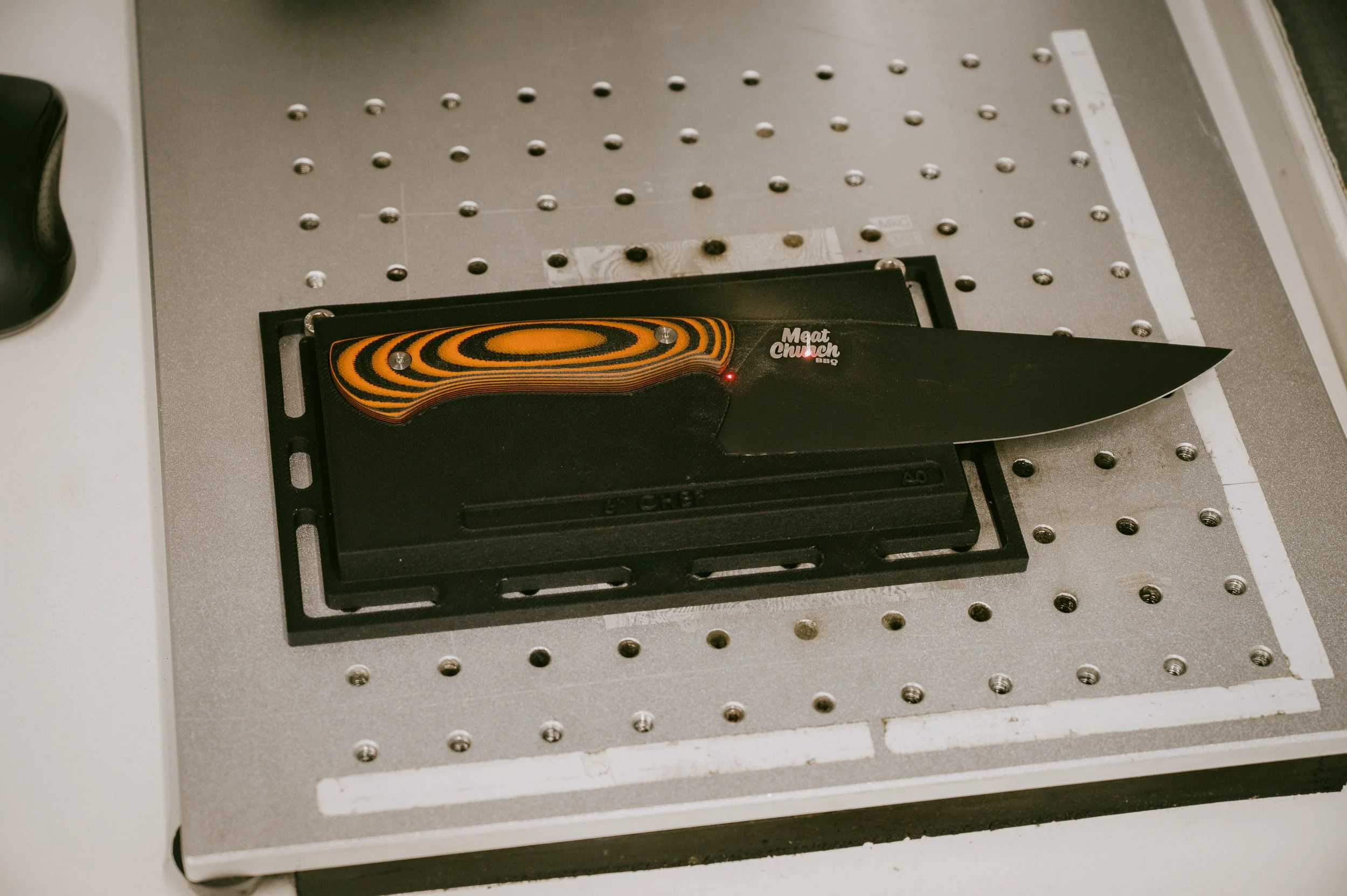

Smith said he hasn't compromised on his commitment to selling knives that are 100 percent American made, even though he's competing with big-name knife brands. Even the handles and sheaths on his knives, for example, are produced in-house from 3D-printed Kydex plastic. The knives themselves are made from a combination of 52100 Ball Bearing Steel and Magnacut Stainless Steel—all sourced in the United States.

"I wanted to combine my skills in metallurgy, edge geometry, and ergonomics to create a hunting knife that felt more custom," he said, "but on a production scale—and all in the U.S." When you buy one if his knives, it comes with a lifetime warranty that MKC calls the "Generations Program." When the knife needs to be sharpened, you can ship it to the Frenchtown shop where it'll be professionally honed by one of his employees and sent back to you—no charge.

Smith's current blade lineup has grown to include skinning knives, a fillet knife, a hatchet, and a dedicated culinary set. But in the early days, he offered one all-purpose hunting knife. "The Blackfoot Knife was what kicked us off, and it's still very popular," he said. "Then the Speedgoat was next, and that was huge."

These days, the original knife shed next to Smith's home houses his four-wheeler and serves as a staging area for knife-making equipment he shuttles across the country to different trade shows and hunting expos. But he still brings custom knives to life at the work bench next to his wood stove. In the fall of 2024, MKC broke ground on a new facility, just up the interstate from the Frenchtown shop where the company currently operates. "We're going to keep growing,” he said. “I really don't see this slowing down anytime soon. But the focus will always be on quality and affordability—and we will always build our knives to last."